Choosing the right oil for gearboxes and bearings is crucial for the reliable and long-term operation of industrial equipment. Mistakes in selecting lubricants can lead to overheating, accelerated wear, and significant financial losses. Let’s explore the key issues and how to solve them using proven solutions from Mobil.

1. Using the Wrong Type of Oil

Each mechanism requires a specific type of oil, considering operating loads, temperature, and speed. One of the most common mistakes is using universal oil instead of specialized oil. For example, unsuitable gearbox oil can cause overheating and mechanical failures.

How to avoid it?

- Follow the manufacturer’s recommendations.

- Consider operating conditions (temperature, humidity, load).

- Check oil compliance with international standards (ISO, AGMA, DIN).

Mobil Recommendation: To enhance efficiency and equipment protection, use Mobil SHC 600 – a high-performance synthetic oil with superior thermal stability or Mobilgear 600 XP, which provides reliable protection against wear and corrosion.

2. Ignoring Viscosity Grade

Oil viscosity determines its ability to form a protective film between moving parts. The wrong viscosity choice can either cause overheating and excessive energy consumption (if the oil is too thick) or insufficient protection (if it is too thin).

How to avoid it?

- Consider temperature conditions during operation.

- Use oils with the correct viscosity index.

- Adapt to seasonal changes (summer/winter).

Mobil Recommendation: For stable operation in extreme conditions, choose Mobil SHC Gear, which offers a high viscosity index and excellent thermal stability.

3. Using Incompatible Additives

Additives improve oil properties, but the wrong combination can harm equipment. For example, sulfur-containing additives can corrode copper and bronze parts.

How to avoid it?

- Select oils with additives suited to specific materials and conditions.

- Check the chemical compatibility of the oil with machine components.

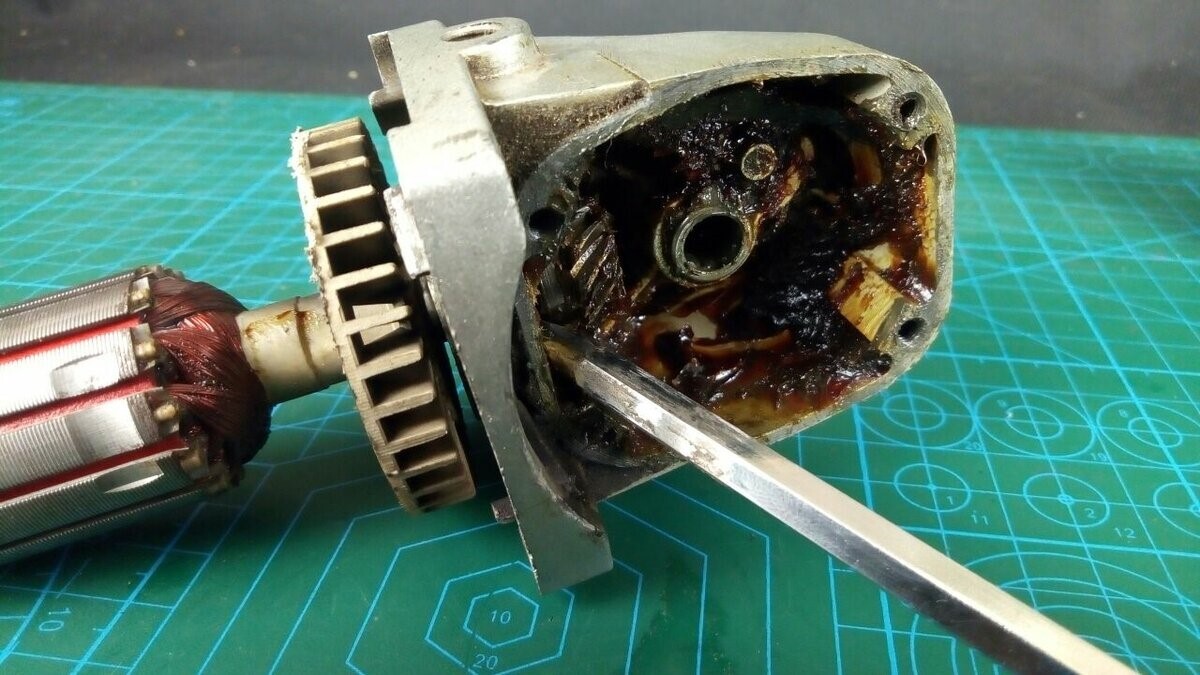

4. Neglecting Regular Oil Changes

Even the highest-quality oil degrades over time: it oxidizes, accumulates contaminants, and loses viscosity. Using degraded oil can accelerate equipment failure.

How to avoid it?

- Follow the recommended oil change schedule.

- Regularly analyze oil for contaminants and signs of wear.

- Use filtration systems to extend lubricant life.

Mobil Recommendation: For long-lasting equipment performance, use Mobil SHC Rarus, which has high resistance to oxidation and contamination.

5. Buying Cheap or Counterfeit Oils

Counterfeit oils do not meet the stated specifications and can cause equipment failure. Low-quality formulations fail to provide adequate protection and may accelerate component wear.

How to avoid it?

- Purchase oils only from official distributors.

- Verify quality certificates.

- Beware of suspiciously low prices, as they may indicate counterfeit products.

Mobil Recommendation:Mobil DTE 10 Excel hydraulic oil offers high wear resistance and low deposits, making it an ideal choice for reliable equipment operation.

Why Choose Mobil and Eurasian Supply?

Eurasian Supply is the official distributor of Mobil in Uzbekistan, offering only original lubricants with guaranteed quality. Partnering with Eurasian Supply gives you:

- Officially certified Mobil products.

- Professional technical support and consultations.

- Nationwide delivery across Uzbekistan.

Selecting oil for gearboxes and bearings is not just a formality, but a critical factor affecting the service life and efficiency of equipment. Mistakes in selecting lubricants can lead to serious losses, so it is extremely important to use proven and certified oils from Mobil. By contacting Eurasian Supply, you receive a guarantee of quality and reliable supplies!

Phones: (+998) 77−577−07−63, (+998) 55−515−15−07.

Address: Yashnabad district, Mahtumkuli street, 81.

E-mail: info@1lubricants.com

Website: 1lubricants.com

Telegram: t.me/mobil1lubricants

Address: Yashnabad district, Mahtumkuli street, 81.

E-mail: info@1lubricants.com

Website: 1lubricants.com

Telegram: t.me/mobil1lubricants